AI is printing the rocket engine that could beat SpaceX at its own game

SpaceX owns 98% of global rocket launches, a monopoly with virtually no competition. Only China is competing with Elon Musk at this point in number of launches and, while the country is getting closer to mass-producing reusable rockets, it appears far from making that happen. The world needs to scramble. We can’t let a single company dominate the future of humanity—and much less one that is owned by Musk.

“If you copy SpaceX, it’ll take you 10 years to get where they are today,” Lin Kayser, cofounder of Dubai-based engineering AI firm Leap 71, tells me in a video interview. “But in 10 years, SpaceX won’t be where they are today. The game will be over.” Startups and nations need to catch up to Musk, but that means solving a brutal equation: designing engines with comparable thrust (measured in kilonewtons, or kN) and efficiency, but without the decade-long development cycles. And to beat SpaceX, you also need to be able to mass-produce the rockets.

This is now more important than ever because the stakes are even higher than just five years ago. Satellite constellations like Starlink, which may soon enable direct-to-phone internet, threaten to sideline telecom operators and centralize control of earth’s critical communication infrastructure on top of controlling the space economy. “Every region needs sovereign launch capability,” Kayser contends. “Otherwise, you’ll pay 10 times what SpaceX pays to access space—if they let you.”

His company may have a solution to fix that conundrum. Leap 71 developed artificial intelligence called Noyron that, so far, has successfully designed two rocket engines. Kayser believes that his company, legacy rocket makers, and startups will be able to leverage this synthetic rocket engineer to create a cheaper match to the SpaceX Raptor—and beat Musk at his own game.

The 10-foot-high Raptor—which powers the Starship—is arguably the most advanced Western rocket engine in production. Its latest iteration produces 280 tonnes of thrust at sea level, surpassing competing engines like Blue Origin’s BE-4. It uses methalox, an efficient fuel that can be manufactured in places like Mars, which makes it key for deep-space exploration. But the Raptor’s importance lies in the fact that it is the first operational full-flow staged combustion (FFSC) engine in history. This means that it optimizes efficiency and thrust while minimizing thermal stress, so you can reuse it many times, the key for cheap, sustainable space exploration.

Only two other FFSC engines have been tested, but they’ve never flown. Leap 71 now wants to achieve the same spaces but better, with fewer 3D-printed pieces, which will make it less expensive than Musk’s engine.

Computational blueprint

Leap 71 describes its Noyron computational model as an “engineer brain in a box.” Unlike generative AI tools that require human oversight because they are just guessing what could work, Noyron encodes physics, material science, and manufacturing rules to autonomously design rocket engines. It generates not just shapes but also functional hardware ready for 3D printing. “Traditional parametric CAD is geometry-driven. Ours is physics-driven,” Kayser explains. “Calling it parametric CAD would be like saying ChatGPT is autocomplete.”

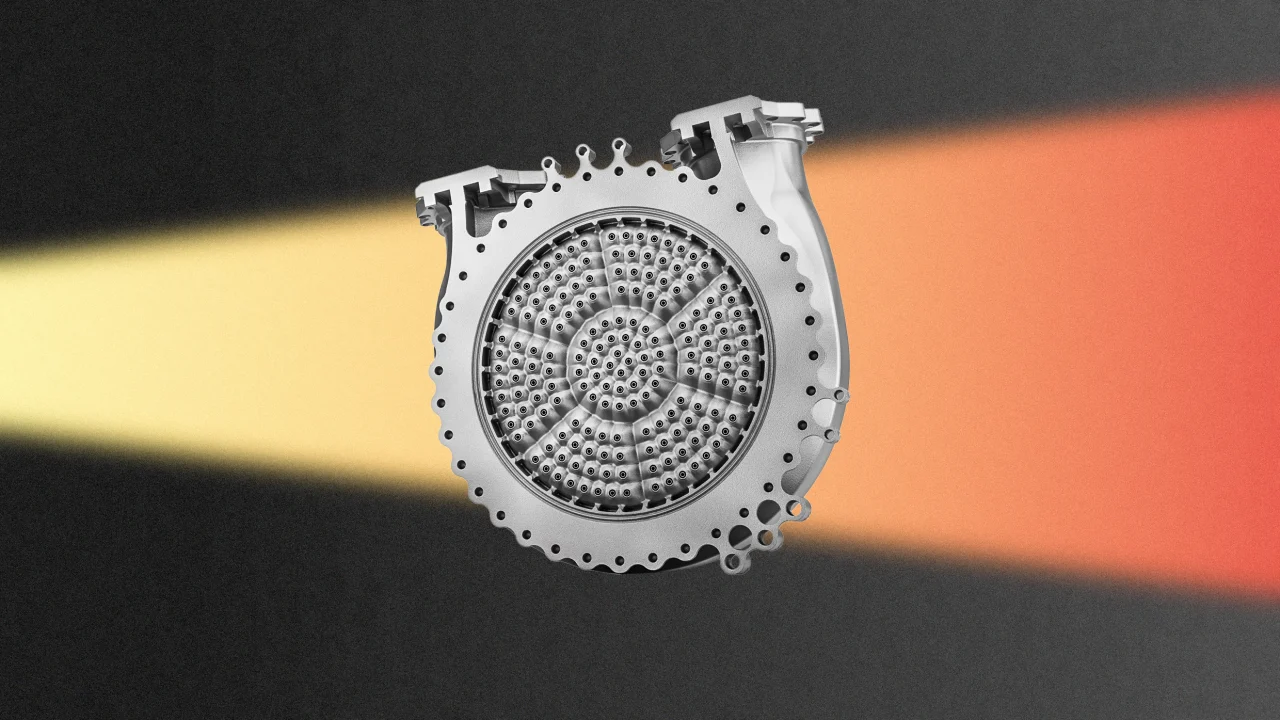

The system’s first breakthrough came in 2024 with a 5 kN rocket engine. The compact, high-efficiency rocket was fully designed by AI and 3D printed in one go as a single-piece copper engine with intricate internal cooling channels. During trials in an old World War II bunker in the U.K., the engine fired flawlessly, validating Noyron’s ability to predict thermal stresses and fluid dynamics. Then, in January 2025, Leap 71 really pushed the envelope by designing one of the most challenging and elusive rocket engines in the aerospace industry: a cryogenic aerospike thruster, an engine capable of working at every altitude to eliminate the need for multiple rocket stages, minimizing elements and costs in the process.

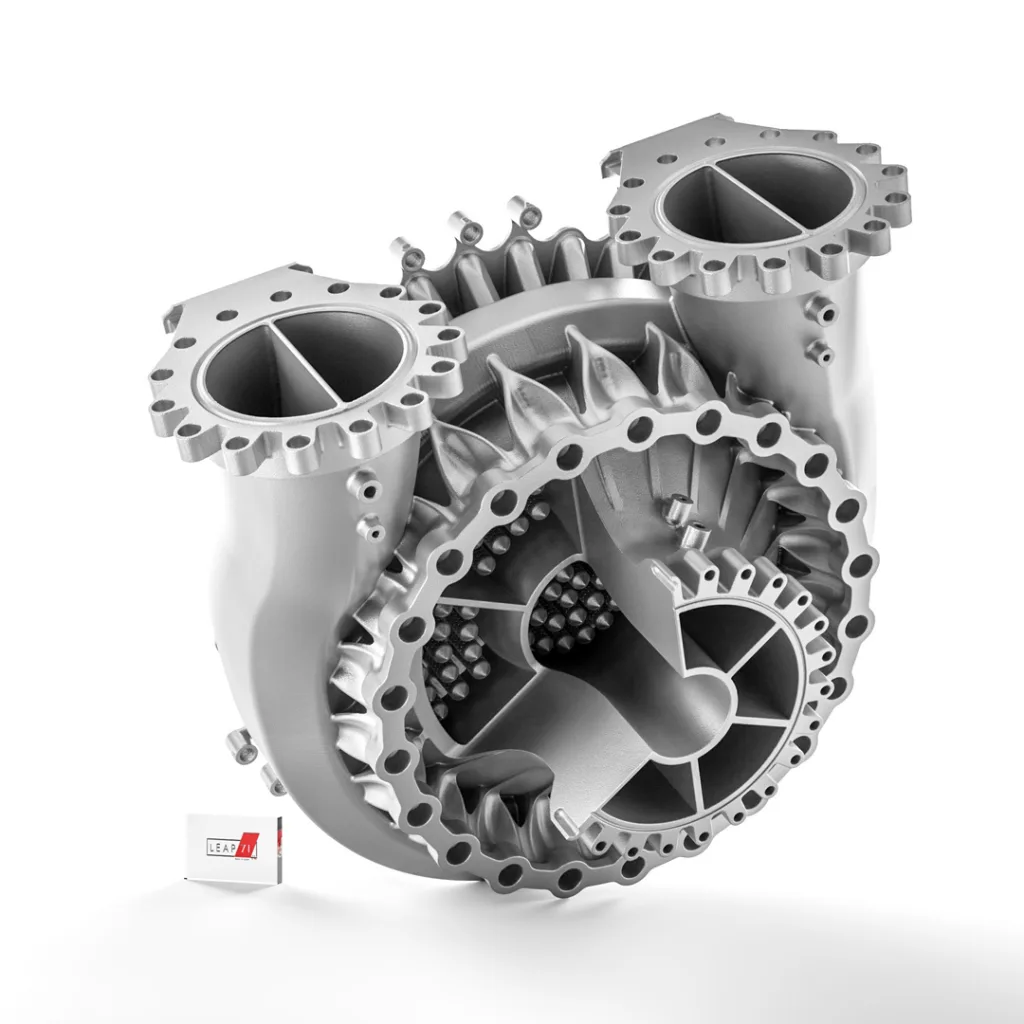

Now the company wants to scale up this approach to engines 400 times larger. The new road map includes two reference designs: the 200 kN XRA-2E5 aerospike and the 2,000 kN XRB-2E6 bell-nozzle engine, equivalent to SpaceX’s Raptor. The first, he says, is slated for testing within 18 months of April 2025 (placing it around late 2026). The second is targeted for readiness by 2029.

For rocket engine development—with design and testing cycles measured in decades—this is incredibly ambitious. But the timeline is achievable because of how Noyron works, Kayser says. Instead of manually iterating prototypes, Noyron treats all engines as variations of a unified “DNA.” And instead of having to be programmed, its edge lies in its ability to absorb decades of engineering knowledge—even from obscure sources.

For its new model, Leap 71 has not only incorporated learnings from its past tests (like data on cooling efficiency and material strain), but also vast amounts of new information, including digitized Soviet-era rocket manuals. “We plug these into Noyron to refine our thermal models,” Kayser says. The AI also learns from every test, creating a feedback loop that collapses design cycles and speeds up the development process.

Noyron is not generative AI, but a computational model capable of producing deterministic results that are consistent every time. They are accurate according to the actual physical world and data. It understands. It doesn’t just guess. Input the same specs, and it generates identical designs (try that with ChatGPT, Gemini, Midjourney, or Sora). This is critical for aerospace reliability. “Human engineers can see the rationale behind every decision,” Kayser says. “It’s not a black box.”

The challenges

While Noyron can design a rocket engine in minutes, proving it works in the physical world is the real test. The company’s ambitions collide with a stark reality: Even the most advanced AI cannot shortcut the laws of physics and bureaucracy.

Securing test facilities for large engines is another hurdle. While smaller subsystems (like the 28 kN turbopump it wants to test this year) fit on existing stands, the 2,000 kN engine’s sheer size demands specialized infrastructure. “The critical path here is test-stand availability,” says Kayser.

Current options are scarce and scattered around the world. Shipping engines abroad triggers export controls and delays—a problem compounded by geopolitical tensions. Moving a small engine from Germany to the U.K. already takes “two to three weeks,” Kayser tells me. That’s why Leap 71 is in talks with governments in Dubai, Singapore, and New Zealand to co-locate manufacturing and testing. Oman’s planned spaceport and New Zealand’s remote Tāwhaki facility, with its vast sound-dampening landscapes, are leading candidates. “You can’t just put a loud rocket engine next to a city,” Kayser says.

The other challenge—the actual production of the engine—has only just become possible, with China’s new 3D-printing behemoths capable of producing parts that are 6.56-by-6.56-by-3.60 feet. In fact, this is what led Kayser and his partner, Leap 71 cofounder Josefine Lissner, to believe that making a Raptor-class engine was even possible. Called the EP-M2050 (and manufactured by Eplus3D), this colossal 3D printer uses 36 lasers to turn metallic powders into all the parts needed for next-gen rocket engines, including the nozzles, which will be much taller than your average human.

The printers are so new that quality assurance is still a question mark. Surface roughness, inherent to layered metal printing, disrupts fluid dynamics in cooling channels. Rough walls increase friction, altering fuel flow and thermal stability. Post-printing, parts undergo rigorous cleaning to remove residual metal powder, a task that until now has been handled by German firm Solukon because “any impurities could cause an explosion,” Kayser says. Material uniformity is another gamble. While printers handle alloys like copper-chromium-zirconium, ensuring consistent strength in massive components—especially under the violent vibrations and thermal swings of a firing engine—remains unproven at this scale.

The turbopump, which forces fuel into the combustion chamber at extreme pressures, epitomizes this challenge. Leap 71’s 28 kN test rig validates principles for larger designs, but scaling amplifies risks. Turbines spin at supersonic speeds, generating centrifugal forces that warp metal. Rapid temperature shifts—like the -297°F cryogenic oxygen flow meeting 5,430°F exhaust—threaten cracks. “Sealing, material fatigue, and transient conditions during start-up and shutdown are critical,” Kayser explains. “These are not just design problems—they demand practical testing.”

That’s why the most unnerving hurdle of rocket development with this method is “blind testing.” Leap 71’s aerospike engine, printed as a single copper block with internal cooling channels, could not be inspected internally before firing. “We had to test blind,” Kayser says. During trials, imperfect oxygen flow led to higher-than-expected temperatures. Although it all worked, it forced an early shutdown. “Instead of risking additional runs, we cut the engine in half to analyze it,” Kayser adds. Each failure feeds back into Noyron’s models, but iteration consumes time and capital.

For now, Leap 71’s strategy hinges on incremental validation—testing subsystems like injectors and turbopumps individually—while lobbying governments to fund dedicated test facilities.

The road ahead

While these are big challenges, they are not insurmountable. The space industry knows it and, according to Kayser, wants a piece of the action. Everyone is looking for a way to leapfrog several years and catch up to—or surpass—Musk. Right now, Leap 71 collaborates with about 15 rocket startups. Kayser can’t disclose their names under confidentiality agreements except for the Exploration Co., which is developing a European Moon lander. These partners lack SpaceX’s vertical integration but want tailored engines without decade-long R&D.

“The engine is the most expensive and complicated part,” Kayser emphasizes. “Everyone else just buys them. But there’s no supply.” L3Harris—which now owns the legendary rocket engine maker Aerojet Rocketdyne, makers of the Apollo engines—wants to sell them, but it doesn’t have anything comparable to the Raptor. Blue Origin makes and sells engines for the United Launch Alliance (ULA), but nobody else. The Russian NPO Energomash once dominated the global rocket engine market, supplying the RD-180 that powered ULA’s Atlas V rocket for decades. But RD-180s are now considered relics—and are under sanctions because of the Ukraine war, anyway.

“[Current design processes] are actually a problem for many of the micro launcher companies right now,” Kayser says. “So they have relatively small engines. And if they now want to play in the higher leagues, they basically have to embark on a completely new project, create a completely new rocket.” The main differentiation between sizes is the engine, because the rest of the rocket is scalable. It’s harder to scale up the engine because it has completely different specifications and requirements.

By using Noyron, Kayser says customers will be able to fine-tune to their own needs and input thrust, fuel type, and size to receive bespoke engine designs for every need. A startup might tweak an aerospike for methane fuel, while another firm could optimize for cost. Some engines will be small and some could be Raptor-class.

We will know if it all works in just a couple of years, so we won’t have to wait long: Kayser tells me that he and Lissner expect the first hot firing of the 200 kN XRA-2E5 aerospike engine in October 2026. Full-scale testing of the large 2,000 kN Raptor-class engine is tentatively planned to begin in 2028, with qualification for flight readiness stretching into 2029.

If Leap 71 can pull it off, it will be phenomenal for humanity. A new process for rocket development will challenge Elon Musk at his own game and democratize the means to reach orbit for every country on the planet. Plus, if it happens, the dream of having Tony Stark’s J.A.R.V.I.S.-like AI to aid humans to build the future will be real. Kayser certainly believes in it: “We’re building a world where anyone can engineer complex machines.”

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0

![Criminal Minds Star Breaks Down That ‘Seminal’ Moment for Series, How the Devastating Twist Will Affect [Spoiler]](https://tvline.com/wp-content/uploads/2025/05/criminal-minds-will-dies-jj-husband-season-18-episode-2.jpg?#)