These former Amazon robotics executives just landed $20 million to tackle the housing crisis

Over the course of a decade at Amazon, Vikas Enti helped lead the retail giant’s deployment of robots in its fulfillment centers. Then he started thinking about how the same skills could be applied to one of the world’s biggest challenges: how to build low-carbon, affordable housing.

“The biggest catalyst was me becoming a dad of twin daughters,” he says. “My kids being born prompted introspection on where else I could be applying my skills that had greater benefits to society.”

He knew that the U.S. has a shortage of millions of homes, and a shortage of hundreds of thousands of construction workers. He also knew that buildings, which are responsible for around 40% of global emissions, are a key part of tackling climate change. And he realized that the approach his team had taken at Amazon could translate to the construction industry.

In 2022, along with two other former Amazon employees, Enti cofounded Reframe Systems, a startup that’s using software and robotic microfactories to drive down the cost of building housing. Today the company announced that it raised $20 million in a Series A round of funding led by Eclipse and VoLo Earth Ventures.

Rethinking factory-built housing

The construction industry has been relatively slow to embrace new tech. “It’s been a function of how fragmented the industry is,” Enti says. A home might be built with 25 subcontractors, and each subcontractor is typically a small business. “Construction as an industry has chronically underinvested in R&D because there have actually been very few players that have grown large enough to be able to afford an R&D budget,” he says.

In theory, modular construction in factories could help bring down costs and build more housing faster. But of the handful of companies that have tried to scale up factory-built homes, some have struggled, like Katerra, which raised more than $2 billion before eventually filing for bankruptcy in 2021.

Reframe’s founders started by talking to 18 different housing factories around the world to understand what worked and what didn’t. Some, particularly in Europe and Japan, had succeeded. Others had failed. Reframe also talked to developers to understand what it would take for them to consider switching to a new method of construction.

Before jumping to the step of designing robots, “we really obsessed over the problem,” Enti says. “What does it look like for us to build millions of residential homes that are great for the planet but also great for people’s wallets?”

They landed on three main requirements. If they were going to build factories, they needed to be very cost-efficient and fast to build—less than $5 million and possible to deploy within 100 days. (By contrast, one of Katerra’s factories reportedly cost $150 million to build.) Additionally, each home needed to be cost-efficient to build, with at least 35% gross margins. And the factories needed to be easily adaptable to local zoning requirements that change from city to city.

Mass customization

Most factory-built housing takes an assembly-line approach. But Enti argues that it doesn’t work. “People say if you could only mass-produce homes the way you mass-produce cars, everything would be better,” he says. “The reality is when you look at the nuances of site conditions with 30,000 zoning jurisdictions in the country and with different state codes, it’s very hard to get one product that actually fits all these constraints.”

Instead, he says, Reframe Systems embraces the idea that construction is highly local and diverse. “We’re not going to fight it,” he says. “So what technology do we need to develop so we can actually build snowflakes at scale?”

It’s not unlike the challenge they faced in Amazon’s fulfillment centers, where each order was unpredictable. “You let the customer pick and choose anything they want—a red pen, blue pen, and teddy bear in the same order—and the job of the software and the robotics in the background was to make sure that the marginal cost to deliver this variability was zero,” Enti says.

For housing, that meant developing custom software that can adapt to zoning codes, site requirements, or the architectural style that the property owner prefers. (Cosmic, another startup, is taking a similar approach.) The system also needed the ability to easily switch between housing types, from accessory dwelling units to single-family homes to apartment buildings. Reframe is particularly focused on “missing middle” housing, like duplexes and other small multifamily buildings.

“We effectively have to invent what we call a high-mix, high-volume manufacturing process, which breaks the assembly line,” Enti says.

In two of its first projects, currently under construction in Somerville, a suburb of Boston, the company is building two three-story triplexes. The designs are similar, but because one building sits on a corner, it has different requirements, including additional windows on one side. It’s the type of change that could be complex in traditional construction, but it took Reframe only a day to adjust and produce new plans.

How the system works

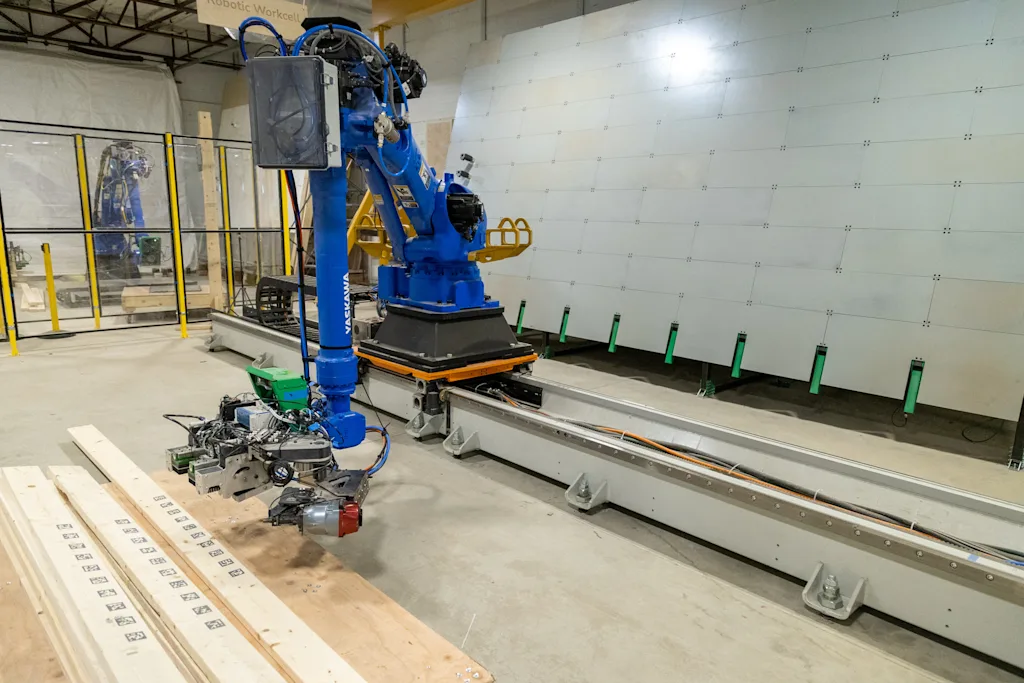

At the company’s first microfactory, near Boston, it builds modules that are as fully finished as possible, such as kitchens complete with appliances. Then the modules can be delivered nearby and assembled on a building site. So far the company’s robot performs only a tiny fraction of the work: A robotic arm frames walls and ceilings. Reframe Systems aims to eventually automate around 60% of building tasks.

Wiring and plumbing is installed in walls and floors by workers at the factory. Parts are precut and printed with instructions. The company’s goal is to make it feel more like assembling Ikea furniture or a Lego kit, in an industrialized way. Enti says even workers who are new to construction can handle complex steps through the process.

The company’s approach can cut costs in a few different ways. First, Enti says, by eliminating subcontractors, it can reduce the markups that get passed on to customers. Building in a systematic way in a factory helps cut the use of materials, another major source of cost. The process is more efficient for workers, cutting the cost of labor. It’s also two to three times faster than traditional construction, so if a building is constructed for a developer, they can start getting returns more quickly. The houses are also ultra-efficient and wired for solar power and batteries, so residents can save money on electric bills.

A network of microfactories

The first microfactory is around 18,000 square feet, but later factories will be 50,000 square feet, or roughly the size of the garden center at a Home Depot. Reframe envisions running a network of factories across the country.

The next location will be in Southern California, where the company plans to help rebuild homes in Altadena that were destroyed by the wildfire in January. The team is currently getting feedback from residents on single-family bungalows designed to fit into the neighborhood, from a Spanish-style house to a Craftsman cottage.

At first, the company plans to build a handful of homes at its Massachusetts factory and ship them to California. Then, as it proves the demand is there, it plans to build a second microfactory in Los Angeles.

“This is going to be our playbook to enter new markets,” Enti says. “We will always try to have demand precede capacity because we can launch our factory in 100 days. So the goal is that we ship product from existing factories to a new market, use that product to drum up demand, and then we convert that to go set up a new microfactory.”

Reframe wants to build a million homes by 2045. (For reference, it took D.R. Horton, the largest builder in the U.S., about twice as long to build a million homes.) That would require around 800 microfactories to be up and running.

“They might seem like large, scary numbers,” Enti says, but he points to Amazon, where the robotics team built only 300 robots in its first year a decade ago, but recently built its millionth robot.

“It’s very hard to forecast exponential growth and scale,” he says. “My message to the team is it’s always going to be one home at a time, one microfactory at a time. But every microfactory that we build will be responsible for seeding the team that’s going to build five more microfactories. The demand is there—the need for housing is there.”

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0