This flying wind turbine can pull power from high in the sky

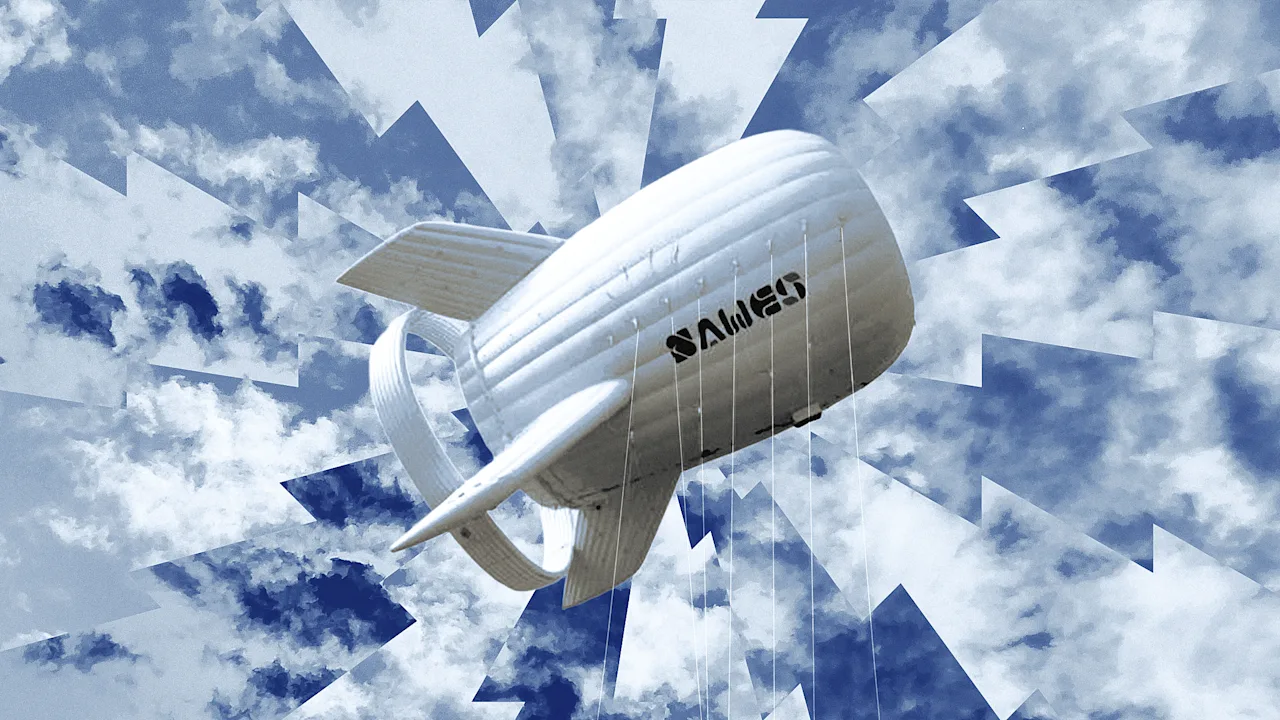

Wind turbines usually jut up from the ground like giant pinwheels. Now a company in China is exploring a new form factor: flying wind turbines. These zeppelin-like aircraft float high in the sky, tethered to the ground only by cables as they generate a nonstop stream of power thanks to the strong winds present in the upper layers of the atmosphere.

Rather than being throttled by capricious ground-level winds—one of the main challenges of current stationary turbines—flying wind turbines’ power throughput will not fluctuate because the wind there is constant. The design could solve some of the biggest problems of wind power generation without having to invest in extensive infrastructure, reducing wind power’s environmental footprint in the process.

The concept was first proposed by a Chinese engineer who was among the pioneers of NASA’s Jet Propulsion Laboratory in the mid-1940s. It never took off in the U.S., but the Chinese energy startup Sawes claims it is ready to deploy thousands of floating turbines that can produce 100 kilowatts, which is the same output of the ground windmills that now power everything from small to midsize commercial structures and agricultural operations to industrial facilities and even small municipal projects. Sawes is also working on a new model that will match the capabilities of typical ground windmills with a turbine that can generate more than 1 megawatt.

A clever idea

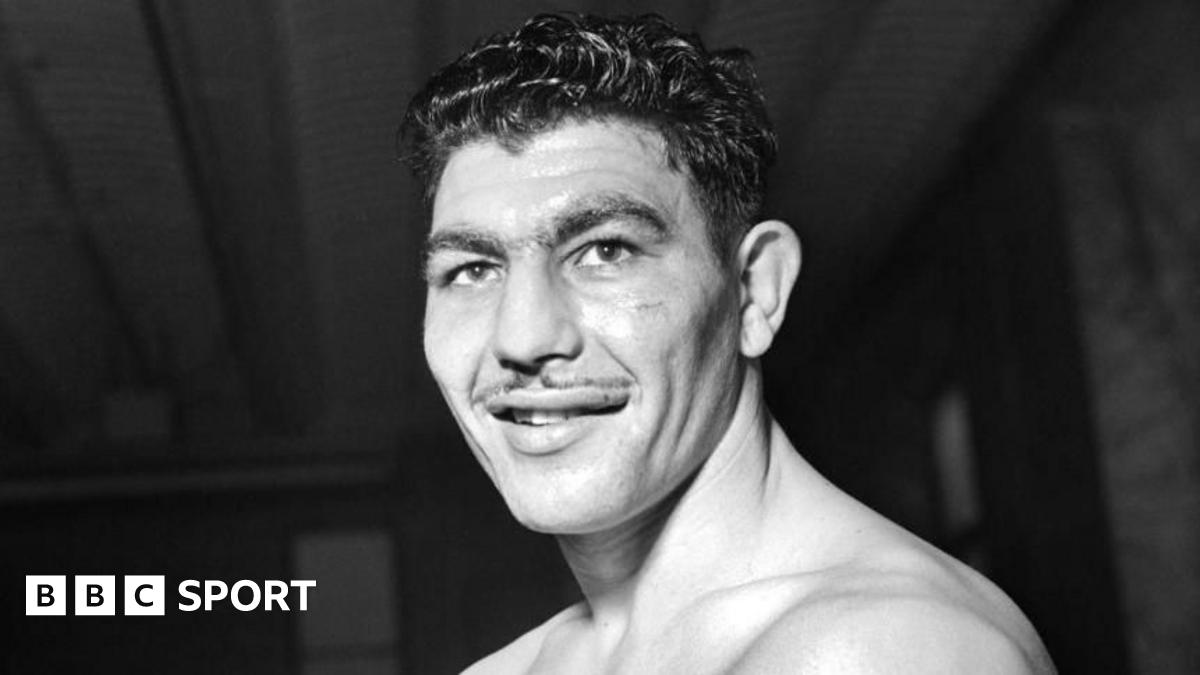

The origins of airborne wind power go back to Shanghai-born aerospace engineer Qian Xuesen. Qian had fled 1930s China to study at MIT before joining Caltech’s famous “Suicide Squad,” the rocket-obsessed engineers who laid the foundations of modern American spaceflight.

He was a brilliant immigrant who helped build one of the most important American technological revolutions of all time, but Qian’s career in the U.S. ended in the shadow of McCarthy-era suspicions. After years under house arrest, he was deported to China in 1955, where he became the founding father of the Chinese missile and space program. His research was the foundation for the Long March family of rockets that has made Beijing a space superpower.

That was also the time when he came up with the theories that make the current flying wind turbines possible. In 1957, Qian proposed what he called the “ejector diffuser duct,” a theory that the airflow through a turbine could be dramatically accelerated by adding a carefully designed circular housing around it. Instead of treating wind as a free-stream mass passing through open blades, Qian’s idea reframed the turbine as part of an aerodynamic system.

The ring-shaped duct would create a pressure difference (low pressure behind the turbine, higher pressure in front) that pulled additional air into the blades. This effect, essentially a man-made “throat” for the wind, could increase efficiency significantly without requiring larger blades or taller towers. Whereas conventional ground turbines rely purely on swept blade area, constrained by physics and structure, Qian’s ejector diffuser model effectively multiplies the usable wind without increasing structural weight.

Qian’s concept sounded outlandish at the time. Turbines were still niche engineering projects, and energy planners had little appetite for experimental designs. It wasn’t until much later that they started to take shape.

Crashing dreams

It wasn’t easy. Concepts are cool, but engineering and manufacturing them is often extremely difficult, which has resulted in a lot of roadkill. Over the decades, many have tried to turn flying wind turbines into working machines.

The MIT spinout Altaeros built a helium-filled blimp with a wind turbine at its core, hoping it would hover at 2,000 feet to capture faster winds. “We try to invent as little as possible,” CEO Ben Glass told NBC News in 2014, explaining that Altaeros simply repurposed proven blimp and turbine tech. Despite promising tests in Alaska, the company abandoned the power dream and pivoted to wireless communication platforms to deploy local networks using blimps.

Italy’s KiteGen built a kite-like system that flew in figure-eight patterns, pulling generators on the ground. It never moved beyond prototype stage. Makani Technologies, founded in the Bay Area and acquired by Google in 2013, tried a tethered glider equipped with rotors; it was shut down by Alphabet in 2020. Even NASA dabbled with concepts. None made it to large-scale deployment, although we may see a flying kite electricity generator on Mars or some other planet one day.

All of them wrestled with the same problems: engineering complexity, flight stability in high winds, government permits, and natural gas undercutting wind costs. Plus, fixed wind turbines work great for large installations, despite their cost, time, and environmental impact.

Why flying turbines?

The allure of flying turbines lies in their access to stronger and steadier winds. Conventional towers can only reach up to about 650 feet above ground, where winds still fluctuate. But at 5,000 feet, air currents move three times faster and can generate up to 27 times more power.

These turbines’ advantage is not only their theoretical constant power throughput but also their cost. Fixed wind turbines are enormously expensive and resource-intensive to build and install, far beyond the cost of manufacturing the rotor and tower alone.

Each land-based turbine requires hundreds of tonnes of steel, concrete, and industrial components, plus massive construction sites, and, often, new roads or blasting of mountaintops to transport and position equipment. Offshore designs demand steel lattice towers weighing thousands of tonnes, specialized marine facilities, and complex logistics.

These infrastructure needs translate to substantial environmental impacts: huge land footprints of up to 80 acres per turbine, habitat disruption, restricted land access, and months or years of planning, permitting, and construction. With restricted use around the turbines due to noise and safety hazards, much of the land becomes inaccessible—even to the owners.

In contrast, flying turbines like those developed by Sawes weigh less than a ton, require no permanent foundation or land clearance, and can be deployed rapidly where conventional power cannot reach with minimal disruption and cost: remote oil fields, small islands, or disaster zones where speed and mobility matter most.

Sawes began research on its airborne generators using Qian’s ideas in 2017. The company considered using a main helium airbag integrated with a ring wing that accelerates airflow and channels it directly through the embedded generators, theoretically boosting efficiency by more than 20%.

By October 2024, the company’s S500 prototype reportedly hit 1,640 feet and generated 50 kilowatts—breaking global records for both altitude and output, which until then had belonged to a research team at MIT. In January 2025, the S1000 doubled that altitude and crossed the 100-kilowatt threshold.

There are still challenges. Safety, for example, remains a constant question. At those altitudes, winds can quickly become violent. Weng Hanke, chief technology officer at Sawes, explained to the Hong Kong newspaper South China Morning Post that the company’s dual system technology—radar on the ground and sensors in the airbag—ensures stability. In extreme conditions, “the system can rapidly descend within five minutes,” he said.

There’s also the issue of helium. These things work in a similar way to weather balloons, and there’s always leakage, which puts in question their durability. Dun Tianrui, founder and CEO of Sawes, told the South China Morning Post that the company’s aerostat’s gas leakage has been reduced to the point where it can stay in the air for more than 25 years.

According to Sawes, batch production has already begun in Yueyang, a city about 700 miles southeast of Beijing, with contracts worth more than $70 million. The company’s ambition, meanwhile, stretches even higher.

Next stop: The stratosphere

Sawes is now preparing for a test flight of its new S1500 model. “The newly developed S1500 system boasts a generation capacity of 1 megawatt, equivalent to that of a traditional 100-meter-high wind turbine tower [and] is scheduled for its test flight soon,” Weng claimed. “High-altitude wind is a powerful and mostly unused energy source. . . . Once these systems are built in large numbers, the power they produce could be as cheap as from normal wind turbines.”

The design has the same distinctive duct-ring airframe that accelerates airflow. Inside, 12 micro-generators made of carbon fiber operate in parallel, and will deliver utility-scale power from a unit weighing 90% less than a steel tower turbine.

Tianrui envisions fleets of megawatt-class aerostats operating in the stratosphere, more than 32,000 feet up, where wind energy is said to be 200 times more powerful than at ground. “At that time,” he said, “the cost of electricity will be one-tenth of what it is today.”

Such dreams underline both the promise and the challenge of airborne wind power. The world has seen airborne wind startups rise and fall. Whether Sawes can succeed where Google, MIT startups, and European engineers failed depends on scale, economics, and staying power. For now, they hold the record for the highest, most powerful flying turbine ever built—a dream first imagined nearly 70 years ago that may finally be ready to take flight.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0