What Is a Material Inventory Management System and How Does It Work?

A Material Inventory Management System (MIMS) is an essential tool for businesses to effectively track and manage their raw materials and components. It utilizes technologies like barcode scanning and RFID for real-time inventory tracking, ensuring accurate stock levels. By integrating with procurement and production systems, MIMS provides timely alerts for low stock, which helps in making informed decisions. Comprehending how MIMS functions and the advantages it offers can greatly influence your operational efficiency and customer satisfaction.

Key Takeaways

- A Material Inventory Management System (MIMS) tracks and manages raw materials and components for efficient inventory control.

- MIMS automates stock level monitoring with real-time updates, preventing stockouts and optimizing cash flow.

- Integration with ERP and accounting systems enhances operational visibility and supports informed decision-making.

- Advanced tracking technologies like barcode scanning and RFID ensure accurate inventory updates and facilitate timely reordering.

- MIMS improves procurement processes, reduces holding costs, and boosts overall operational efficiency.

Definition of a Material Inventory Management System

A Material Inventory Management System (MIMS) serves as an essential framework for businesses to efficiently track and manage their raw materials and components necessary for production.

This structured approach automates monitoring stock levels, providing real-time updates and alerts for reordering materials, which helps prevent shortages or overstocking. Typically, MIMS integrates with other business functions, such as procurement and production planning, ensuring seamless operations.

By utilizing a material tracking system, companies can apply various inventory valuation methods like FIFO and LIFO, which accurately reflect material costs on financial statements.

Furthermore, leveraging construction material management software allows businesses to forecast material needs based on historical sales and market demand, in the end improving efficiency and minimizing waste in production processes.

Importance of Material Inventory Management

Effective material inventory management is crucial for any business aiming to maintain operational efficiency and meet customer demands. By utilizing construction material tracking software or material tracking software, you can guarantee the right stock levels of raw materials, minimizing the risk of stockouts that could lead to lost sales and customer dissatisfaction.

Furthermore, effective management optimizes cash flow and reduces carrying costs associated with excess inventory, as reported by industry studies. Companies that adopt robust inventory software for the manufacturing industry can cut holding costs by up to 30%.

In addition, implementing practices like Just-in-Time (JIT) and Materials Requirement Planning (MRP) improves your response to market fluctuations, guaranteeing compliance with financial regulations and supporting transparent reporting.

Key Features of Material Inventory Management Systems

When you implement a Material Inventory Management System, real-time inventory tracking becomes a key feature that guarantees you always know your stock levels.

This system not only offers timely updates but additionally integrates seamlessly with other platforms, like ERP and accounting systems, allowing you to maintain a cohesive view of your inventory data.

With these capabilities, you can streamline operations and make informed decisions that improve overall efficiency.

Real-Time Inventory Tracking

Real-time inventory tracking serves as a crucial component of material inventory management systems, enabling businesses to maintain a precise overview of stock levels at any given moment.

This feature allows you to monitor stock continuously, ensuring immediate updates on material availability and demand fluctuations. Advanced systems often employ barcode scanning or RFID technology for automated tracking, which improves accuracy in inventory counts.

With real-time tracking, you can quickly spot discrepancies between physical stock and recorded inventory, minimizing the risk of stockouts or overstock situations.

Moreover, these systems provide instant alerts for low stock levels, allowing timely reordering. Real-time data analytics further empower you to make informed decisions based on current inventory trends, optimizing your purchasing and production processes effectively.

Integration With Other Systems

Integration with other systems is a crucial feature of Material Inventory Management Systems (MIMS), offering businesses a thorough approach to inventory management. By integrating with Enterprise Resource Planning (ERP) systems, MIMS allows seamless data exchange across finance, sales, and production.

These systems typically include API capabilities, enabling connectivity with third-party tools for real-time updates and efficient workflows. You can improve order management by synchronizing inventory levels with purchasing and sales channels, guaranteeing stock aligns with customer demand.

Moreover, integrating with accounting software guarantees accurate financial reporting by tracking material costs directly linked to financial statements. Many advanced MIMS utilize cloud technology, making data accessible from multiple locations, providing real-time visibility for all stakeholders in the supply chain.

How Material Inventory Management Systems Work

Material Inventory Management Systems (MIMS) work by utilizing real-time inventory tracking to keep you informed about stock levels and movements.

This technology automatically updates your inventory status through tools like barcode scanners and RFID tags, so you always know what you have on hand.

Furthermore, MIMS sends automated reorder notifications when stock reaches predetermined levels, ensuring you maintain ideal inventory without the risk of running out.

Real-Time Inventory Tracking

As businesses endeavor for efficiency in inventory management, technologies like Symbol Technologies and Impinj play a crucial role in tracking stock levels in real time. This real-time inventory tracking improves accuracy and efficiency in your inventory management processes. With continuous updates on stock availability, you can make informed decisions about replenishment and order fulfillment without delays. By integrating sales data and demand forecasting, these systems align stock levels with actual consumption, reducing the risk of stockouts or overstock situations. Advanced software can automatically alert you when inventory reaches set minimum thresholds, facilitating timely reordering.

| Feature | Benefit |

|---|---|

| Barcode Scanners | Instant stock level updates |

| RFID Tags | Accurate location tracking |

| Sales Data Integration | Enhanced demand forecasting |

| Automated Alerts | Timely reordering |

| Operational Efficiency | Cost savings and profitability |

Automated Reorder Notifications

Automated reorder notifications play a crucial role in maintaining ideal inventory levels, ensuring you can meet customer demand without delay.

These systems trigger alerts when stock levels hit predefined reorder points, preventing stockouts and ensuring timely replenishment. Utilizing real-time data tracking, you’ll receive immediate alerts about low stock items based on actual consumption rates.

By integrating with sales forecasting tools, these notifications adjust reorder thresholds according to demand patterns, reducing the risk of overstocking or understocking. Many systems employ algorithms that account for supplier lead times, ensuring notifications consider the time needed to receive new materials.

Implementing automated reorder notifications can greatly improve operational efficiency, potentially saving retailers over USD 70,000 annually in labor costs.

Benefits of Implementing a Material Inventory Management System

Implementing a Material Inventory Management System can greatly improve a company’s operational efficiency, particularly in procurement and storage processes.

By streamlining these processes, you can reduce holding costs through minimized excess inventory and waste. The automation of repetitive tasks boosts productivity, allowing you to make quicker decisions and fulfill orders efficiently.

Companies that use advanced inventory systems often experience improved accuracy in stock levels, which helps prevent stockouts and aligns better with customer demand.

Moreover, leveraging data-driven forecasting can greatly improve your inventory turnover ratios, ensuring timely replenishment of materials.

In the end, adopting this system can lead to substantial cost savings, with some businesses reporting reductions in labor costs of over $70,000 annually because of improved tracking and automation.

Types of Material Inventory Management Systems

When you’re managing inventory, it’s crucial to understand the different types of material inventory management systems available.

You can choose between manual systems, like spreadsheets and paper logs, which can be cost-effective but may lead to errors, and automated systems that offer real-time tracking for greater accuracy.

Each option has its strengths, so considering your specific needs will help you make the best choice for your operations.

Manual Inventory Management Systems

Manual inventory management systems serve as a fundamental approach for Inventory Source, especially those with limited inventory needs and straightforward operations.

These systems often rely on basic tools like spreadsheets or paper logs to track stock levels and movements, making them a low-cost solution.

Nevertheless, they require regular physical counts to maintain accuracy, which can be time-consuming.

Since manual systems lack real-time tracking, you may face challenges responding to stockouts or excess inventory, potentially affecting customer satisfaction.

Although these systems are easy to set up and require minimal training, they don’t support advanced features like automated reordering or data-driven forecasting, limiting their effectiveness as your business scales.

Consequently, you should consider your operational complexity carefully.

Automated Inventory Management Systems

As businesses grow and their inventory needs become more complex, utilizing automated inventory management systems can greatly improve operational efficiency.

These systems employ software tools to track and manage material inventory in real time, which considerably reduces manual errors. Cloud-based solutions allow you to access data from multiple locations, facilitating remote management.

Types of automated systems include Barcode Inventory Management Systems, which use barcodes for precise tracking, and Warehouse Management Systems (WMS), which optimize storage and retrieval processes.

Many of these systems integrate with other software, such as ERP and accounting tools, providing a thorough view of inventory levels and financial impacts.

Advanced features like predictive analytics and demand forecasting help you make informed decisions, reducing excess stock and minimizing stockouts.

Integration With Other Business Systems

Integrating a Material Inventory Management System (MIMS) with other business systems is vital for creating a cohesive operational framework.

By linking MIMS with Enterprise Resource Planning (ERP) systems, you can manage inventory alongside finance, sales, and production seamlessly. This integration improves efficiency and visibility across departments.

Connecting MIMS to Customer Relationship Management (CRM) systems helps align your inventory levels with customer demand, enhancing responsiveness to market fluctuations.

Moreover, advanced MIMS solutions can integrate with e-commerce platforms to automate inventory updates, ensuring accuracy and reducing stockout risks.

Integration with accounting software supports precise financial reporting and inventory valuation, fundamental for compliance.

Finally, cloud-based MIMS can connect with data analytics tools to optimize demand forecasting and inventory management.

Real-Time Inventory Tracking and Data Analysis

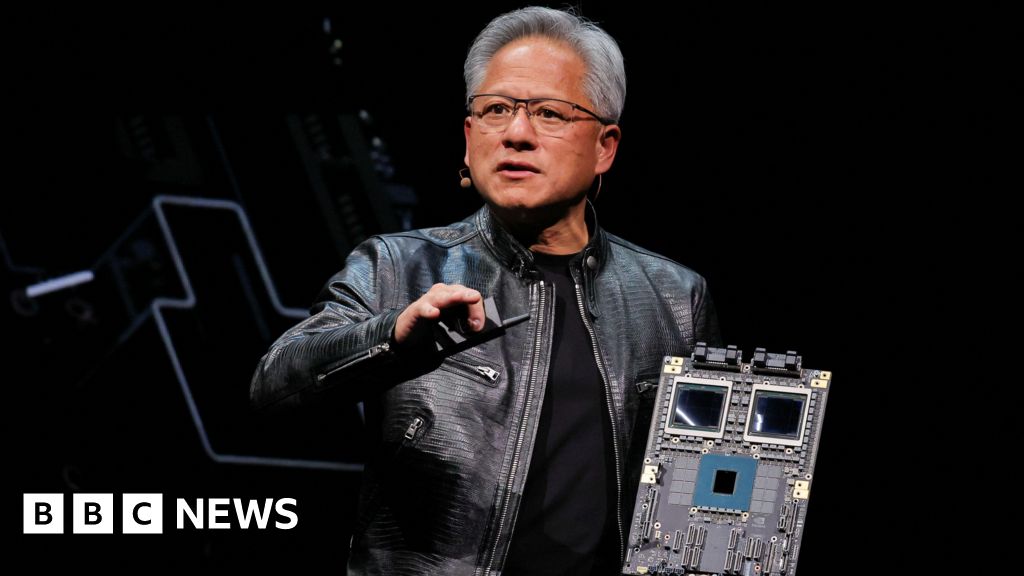

![]()

Real-time inventory tracking is a game-changer for businesses looking to improve their material management practices. By utilizing technologies like RFID and barcode scanning, you get immediate updates on stock levels, boosting accuracy and minimizing risks of stockouts or overstocking.

Data analysis further fortifies your inventory management by examining historical sales trends and turnover rates, allowing you to forecast demand effectively. Here are some key benefits:

- Automated alerts for reordering guarantee timely replenishment.

- Integration with other software provides thorough visibility across the supply chain.

- Real-time data reveals patterns in inventory movement.

- Adjusting purchasing strategies helps minimize waste from slow-moving items.

Incorporating these practices can greatly boost your operational efficiency and decision-making.

Challenges in Material Inventory Management

Managing material inventory effectively presents several challenges that can greatly impact a business’s operations. Excess inventory can lead to unsold stock, obsolescence, and increased carrying costs, all of which strain your budget.

Conversely, insufficient inventory levels may cause stockouts, preventing you from fulfilling customer orders and risking customer satisfaction and loyalty.

Accurate tracking is vital; outdated processes can slow down operations and increase errors in stock management.

Moreover, fluctuating customer demand requires you to adapt your inventory strategies constantly, tracking trends and adjusting stock levels.

Finally, integration issues with existing systems can complicate the implementation of new inventory solutions, making it fundamental to verify compatibility with your current workflows and tools.

Best Practices for Material Inventory Management

Effective material inventory management is crucial for businesses aiming to streamline operations and reduce costs. By adopting best practices, you can improve efficiency and accuracy in your inventory processes.

Here are some key strategies:

- Implement Just-in-Time (JIT): This approach minimizes storage costs by ensuring materials arrive only as needed, reducing excess inventory and waste.

- Utilize a Bill of Materials (BOM): Focus on high-cost raw materials to streamline tracking and enhance inventory accuracy.

- Establish Safety Stock Levels: Determine these based on demand variability and supply lead times to handle unexpected spikes in demand.

- Conduct Regular Audits: Frequent inventory audits help identify discrepancies, ensuring accurate inventory records and effective management.

Case Studies: Successful Implementation of Material Inventory Management Systems

Implementing a Material Inventory Management System (MIMS) can greatly improve operational efficiency and accuracy in inventory practices.

For instance, a manufacturer used MIMS to improve forecasting accuracy, resulting in a 25% decrease in stockouts and a 15% boost in customer satisfaction.

Another case study involving a construction firm showcased a 40% improvement in order fulfillment times, markedly reducing project delays.

Companies adopting MIMS typically see a 20-30% reduction in holding costs through optimized reorder points and minimized excess inventory.

Improved visibility of material flows also aids in making better decisions and responding swiftly to market changes, further driving operational efficiency.

These examples illustrate the tangible benefits businesses can achieve by implementing a robust material inventory management system.

Future Trends in Material Inventory Management Systems

As businesses navigate the intricacies of modern supply chains, future trends in material inventory management systems (MIMS) are poised to reshape how organizations handle their inventory.

Here are four key trends to watch:

- Artificial Intelligence: AI will augment predictive analytics, helping you anticipate demand fluctuations and optimize stock levels efficiently.

- Automation Technologies: Automated guided vehicles (AGVs) and smart sensors will streamline processes, reducing manual labor costs in warehouses.

- Cloud-Based Solutions: The rise of cloud inventory management will provide real-time visibility and accessibility, essential for managing global supply chains.

- 3D Printing: This technology will enable on-demand production, minimizing the need for large raw material reserves and reducing overall carrying costs.

Staying ahead of these trends can greatly improve your inventory management strategy.

Conclusion

To summarize, a Material Inventory Management System is vital for optimizing inventory control and ensuring operational efficiency. By leveraging technologies like barcode scanning and RFID, these systems provide real-time tracking of stock levels and movements. Implementing a MIMS can lead to improved decision-making, reduced costs, and better alignment with customer demands. On the other hand, challenges exist, and adopting best practices is important for success. As inventory management continues to evolve, staying informed about future trends will help you maintain a competitive edge.

Image Via Envato

This article, "What Is a Material Inventory Management System and How Does It Work?" was first published on Small Business Trends

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0

![Wednesday EPs Explain What That Episode 4 Cliffhanger Means for Part 2: Is [Spoiler] Really Dead?](https://tvline.com/wp-content/uploads/2025/08/wednesday-season-2-episode-4-ending-explained.jpg?#)